Select AVISTT services

for

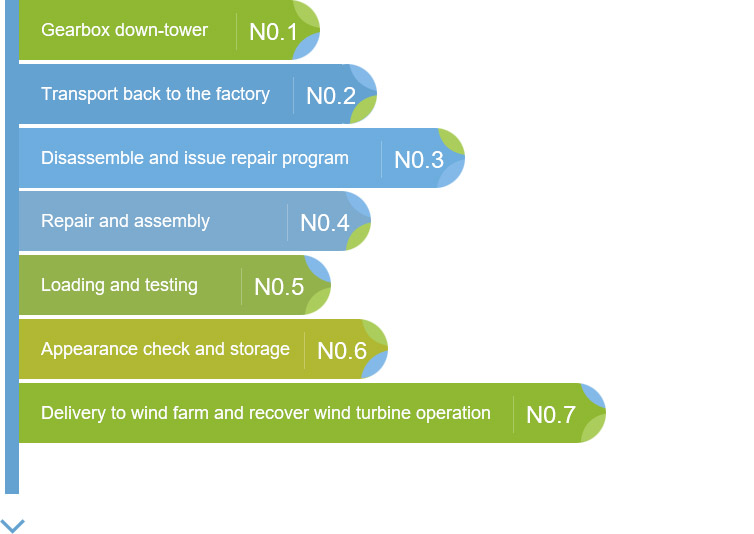

Repair Process

The entire factory repair process for gearboxes is as follows:

A specially-assigned individual will track the implementation of each above procedure. In addition, every repair program needs to be reviewed and only programs which pass review can be issued, ensuring the accuracy of the technology program.

Gearbox down-tower

Under permitting working conditions of the wind farm, the faulty gearbox will be safely and quickly lifted off the wind turbine using professional lifting equipment.

Transport back to the factory

AVISTT will monitor the transportation in real time to ensure that the faulty gearbox will not suffer secondary damage during transportation and will be safely transported back to the factory.

Disassemble and issue repair program

After the faulty gearbox arrives at the factory, engineers will disassemble the gearbox and then issue a detailed repair program based on their findings.

Repair and assembly

Repair and replace parts of the gearbox according to the repair program. After reparations, conduct general assembly of the gearbox based on assembly requirements.

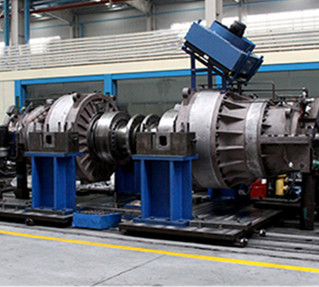

Loading and testing

Implement the loading test according to the gearbox loading test outline and confirm that the test procedure meets the test outline requirements. Record the test procedure and data.

Appearance check and storage

After the testing, paint the gearbox, check for any visible blemishes, and store it in the warehouse. Keep all repair materials on file.

Delivery to wind farm and recover wind turbine operation

Deliver the gearbox to the wind farm. Operation and maintenance engineers will oversee the entire lifting and replacement process to ensure that wind turbine operations is smoothly restored.